This guide describes how to adjust the pilot mixture for those motorcycles that use a fuel screw. If yours has an air screw then just set it to ‘n’ turns out. I use the term fuel screw but most of these circuits are actually supplying a fuel-air mixture.

The pilot mixture will vary slightly depending on temperature so from summer to winter you may need to reset for the season.

This must be done with a warm engine because a cold engine will require a mixture that is too rich, which is why you need to use the choke in cold weather. The process is based on the principle that when the fuel screw is set to the optimum position then that cylinder will achieve its highest idle. You are going to rotate the screw in both directions and take note of where the engine rpm slows. Then you will return the screw to a position midway between those two points. If the number of turns between these two points is too large then this is a strong indication that your engine is suffering from low compression.

Begin by setting the screws to the factory advised number of turns out and the idle to the recommended rpm. Then for each cylinder in turn repeat this process

This is an airscrew. Note that it is on the air cleaner side of the carburettor |

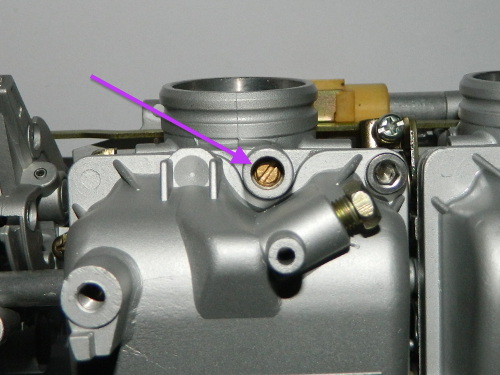

This is a fuel screw. Note that it is on the engine side of the carburettor |

Whilst taking note of the position of your screw, rotate slowly in one direction until you hear the idle begin to slow then slowly reverse direction until, once more, you hear the idle begin to slow. Then set the screw exactly between those two points. As an example, you begin by setting your screw to 2½ turns out according to your workshop manual. Then you turn it in slowly (you are making it leaner) and you notice that after you have rotated ½ of a turn, the rpm begins to slow. That is your first point, at 2 turns out. Now wind it out, first by the ½ turn, so you are now back at your starting point of 2½ turns, and then you continue until at 3½ turns the rpm begins to drop. This is your second point. So the midpoint is actually at 2¾ turns out, being halfway between 2 and 3½ turns out.

Now the idle will be higher than you initially set it because your first cylinder is running a more optimum mixture. You must set the idle speed back down to the correct value.

Move to the next cylinder and repeat the process.

Notice that in the example I gave in the first instruction the difference between the two points is 1½ turns. This is too large, so you should repeat the process for that cylinder to get a finer value. A good result would be that moving the screw by only ¼ or ½ of a turn will drop the rpm.

Finally, many tuners advocate setting on the rich side. So once you find optimum you would wind the screw out by ⅛ to ¼ of a turn. This they maintain will help with the richness that is required during acceleration and cold starting. Conversely, others prefer to leave the screw set in the mid position. Try both and see which one works for your bike.

Now that your idle mixture is correct you will find that to start the bike when hot, just a dab on the button with no throttle, and when cold a bit of choke, and again, no throttle. You will also notice the clean crisp acceleration from low rpm. If your bike does not perform like this or the variation in turns out between the two points when setting your mixture is very large then you have low compression.